The majority of people who come to see me do so for two reasons: 1) they’re looking for a wheel that is bespoke, or 2) they want a set of wheels that is more durable and reliable. In the case of the latter, most riders have typically been burnt not once but twice by previous sets of manufactured wheels. Durability is not always high on the priority list when manufactures are fighting over a few grams on the next sub 1500g wheel set. However the reason many wheels fail is not simply a matter of skimping on weight. Any wheel can fail in the right (or wrong) circumstances. Here are four of the most common reasons that wheels fail.

- Poor quality components and construction

Some wheels never had a chance from the beginning. If you buy a cheap replacement wheel at a shop it was probably purchased wholesale for half the price you paid for it. That means the sum of components, manufacturing and production costs, was less than one quarter of the price you paid for it. Cheap wheels will suffer from poor quality parts and poor build quality. Cheap wheels are a false economy if you intend to get a lot of use from your wheels. Even with high quality factory made wheels, you occasionally get a dud that slips through the various quality control checks.

- Inappropriate design for the rider

A common cause of wheel failure is inappropriate design for the needs of the individual rider. A lightweight wheel designed for road racing will experience greater stress in the hands of +100kg all-weather commuter than say a sub60kg flyweight who only occasionally rides on sunny weekends. The wheel in this case is not necessarily good or bad, its just not suited to the rider and his or her style of riding. Very few professional bike riders weigh more than 80kg. Strength, durability and performance can all be built into a wheel as a matter of design. Performance oriented wheels tend to require a little bit more care and attention than those that are built for durability. The skill of the wheel builder is finding the best match to meet the needs of the individual rider.

- A hard life and/or bad luck

All wheels are consumables and will wear out overtime.. Any wheel that is ridden long enough will eventually fail from the stresses of regular use over many years. Spokes will fatigue over time from the millions of stress cycles. The sidewalls of rims will eventually wear out from brake pad wear. Rims can easily be damaged from an unexpected load such as crashing or hitting an object. In order of failure, rims are typically the first to go, followed by spokes, and then finally the hubs. With a bit of luck, a good set of hubs will last for decades outlasting multiple sets of replacement rims and spokes.

- Poor maintenance and premature fatigue

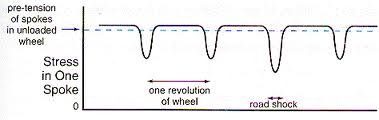

Bicycle wheels are dynamic systems that undergo change through use. Just like the rest of a bike, wheels benefit from a bit of TLC from time to time. Simple things like keeping brake pads clean can reduce premature wear. However the most fundamental form of wheel maintenance involves adjusting and correcting spoke tension within the wheel. Pre-tensioned spokes act a little bit like suspension in that they are constantly undergoing cyclic loading and unloading as the wheels rotate.

(Burgoyne C.J. and Dilmaghanian R. ‘The Bicycle wheel as a pre stressed structure’ J. Engineering Mechanics, ASCE, 119/3, 439-455, 1993.)

Hitting an object such as a pothole can cause a spoke (or spokes) to dramatically unload and subsequently slacken off and loose tension. This change in spoke tension can cause a cascade of effects throughout the whole structure of wheel with neighboring spokes tightening and slackening off. The situation will become worse if unattended. A common mistake many bicycle mechanics make in repairing wheels is to only fix the visually noticeable sign of a wobble in the wheel such as rubbing on brake pads. However, without paying attention to the dynamic structure of spoke tension within the whole of the wheel, the problem doesn’t go away. The customer then comes back to the shop a week later with a faulty wheel and all parties feel frustrated. Like most systems (gears, brakes etc.) on the bicycle, wheels benefit from preventative maintenance to address problems before they get to a point of failure. Wheels that are maintained to a professional standard will outlast those that are given a cursory tweak.